Industrial lighting is essential for the proper manufacturing of many products across different sectors. Industrial lighting is characterized by all the fixtures and lighting types used in factories, refineries, and chemical plants. Industrial lighting depends on the type of business a person runs and how it can be applied on a large scale.

They are made to prevent safety concerns during manufacturing and to follow industry standards. A reliable industrial LED light manufacturer knows how to supply according to the needs of all businesses across multiple industries. Illuminating all areas of production is very important and can only be achieved with the right type of lighting.

What Are The Types Of Industrial Lighting

There are many answers to the types of industrial lighting options depending on the application and the business requirements. LEDs work well when it is covering all the different interiors. No space or blind spots should be left because they can potentially lead to hazards.

After continuous use for many decades, the most common types of industrial lighting were replaced by LEDs because of better efficiency. LED lights are more energy-efficient and allow for a better experience altogether. Many different types of industrial lighting available in the market have their own sets of features and applications. Some of them are:

Halogen Industrial Lighting

Halogen lights and lamps were used for their high brightness and intensity. They give a better white light which is great for the manufacturing process. Their significant applications were headlights and flood lights. The lifetime of these industrial halogen lighting was anywhere between 3000 to 5000 hours. Many types of halogen industrial lighting are available, including parabolic aluminized spots, single-ended quartz, mini-can bulbs, and double-ended quartz. One defining feature of this industrial lighting was that it offered a very concentrated light on a specific area.

Industrial Fluorescent Lighting

Industrial fluorescent lighting is very similar to commercial and residential fluorescent lamps. They were extensively used before LED lights came to the scene and were replaced. CFL bulbs were used for a high lifetime between 9000 and 10000 hours. The wattage and the design of industrial workshop lighting varied depending on whether it was commercial or industrial. CFL bulbs can be used for many hours at a stretch, which is something LED lights also offer. The best results for this particular lighting type can be obtained after they are switched on for multiple hours, ideally during the entire manufacturing process.

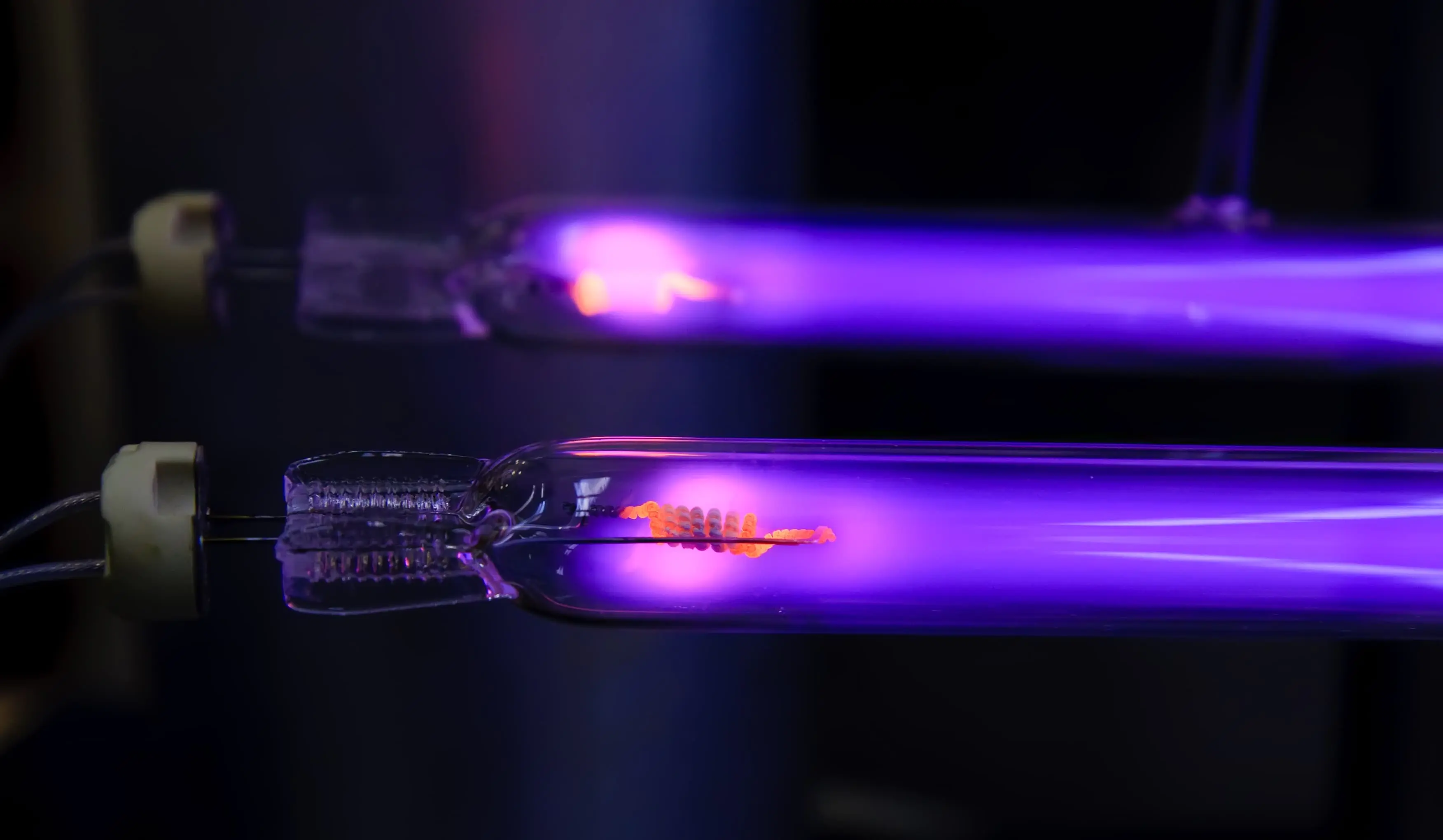

Industrial High-Intensity Discharge (HID) Lighting

High-intensity discharge bulbs were used for a limited number of industrial applications. It is a powerful lighting alternative mainly used for outdoor and general lighting in industrial areas. High-intensity discharge lighting has different types, ranging from metal halide to high-pressure sodium and mercury.

These lights can be used for landscape lighting and outdoor areas. High intensity discharge lighting majorly replaced incandescent bulbs because of a longer lifespan. They have a 20 times longer lifespan than an incandescent bulb beaten by LED lights.

LED Industrial Lights

Light-emitting diodes or LED lights work well for industrial purposes because of their high versatility. LED industrial lights can be adjusted according to the factory space. The Illuminating Engineering Society (IES) recently published a document that industrial LED lights were suitable for industrial spaces like auto shops, retail areas, parking spaces, and warehouses. They also recommended lighting levels in industrial spaces to mitigate safety concerns.

Incandescent Lights

Incandescent lights were the filament bulbs that overheated quickly and provided light by burning the filament. They have a lifespan of about 500 to 1000 hours and are unsuitable for long-term industrial lighting. Better alternatives like LEDs replaced them.

LEDs – The Best Industrial Lighting Solution

There are many benefits that stem from using LED lights across different industrial areas. The greatest benefit of LED lights is that they require little to know repair and absolutely no maintenance to function for long durations of time. They are more durable than any other industrial lighting type and reliable, depending on the manufacturer you choose. LED lights offer a lifespan of more than 50,000 hours.

It can lead to about 100,000 working hours without being shut off for a cool-off period. They are also more energy-efficient than any light bulb used in different industries. Because of their low power consumption, they are also an eco-friendly option compared to incandescent bulbs or high-intensity discharge lighting. Here are some significant reasons industrial LED panels are the best industrial lighting solution.

No Mercury

In contrast to incandescent lights, LED industrial lights do not have any kind of Mercury that facilitates better lighting. They do not negatively impact the health of anyone in the general vicinity. A very common perception people have about LED lights is that they may be harmful to the health of industry workers. They can be used extensively across a factory or refinery. Even if LED bulbs are installed in a high-temperature and high-pressure environment, they will not react negatively. They tend to protect everyone from safety concerns.

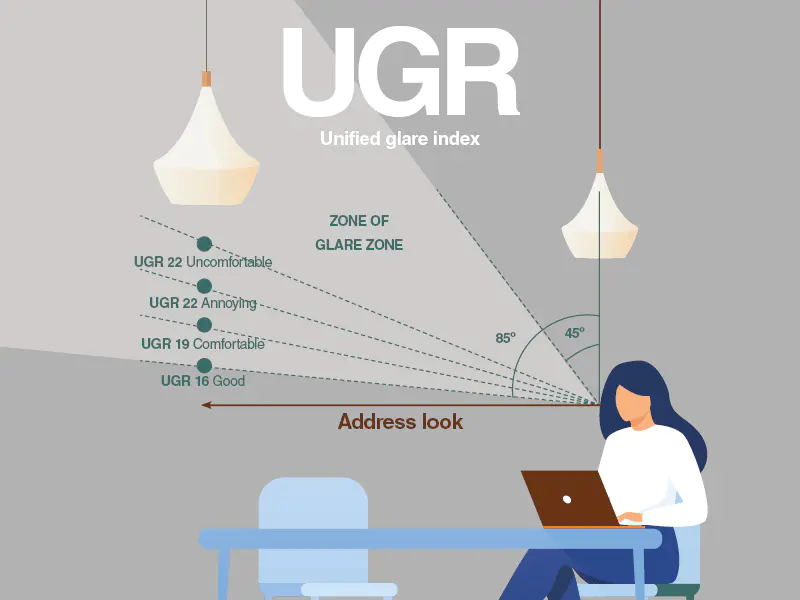

Can Reduce Glare

Since employees work for long periods in any industrial setting, one needs to make that experience as comfortable for them as possible. Reducing glare is possible with LED lights. It does not obstruct the manufacturing process and allows for a clear vision for everybody working in different rooms. In the initial days, the LED lights will have more glare than expected, which is soon subdued. They can easily manage blur and the disadvantages of natural brightness. Production is also related to changes in the color temperature of the LED bulb depending on the production process.

No Maintenance Required

A significant advantage of installing LED lights in an industrial setting is that no maintenance is required. Industries function for significant durations and deal with high temperature and pressure conditions. Maintenance and servicing of machines and equipment are required from time to time. Important too in products that will last for more extended time periods.

Because of a higher lifespan, there is no maintenance needed to open the panels when it is time for a replacement. By learning the industrial lighting design basics of CFL lighting, no maintenance is required at all, which saves a lot of money for the business.

Give a Good Return on Investment

The return on investment in LED lights should be good enough to make the purchase worthwhile for any business. For any industrial setting, one will have to invest in LED lights, which would be a cost for them initially. After installing it, one can easily save a lot of money on regular utility bills because of better energy efficiency. The expenditure initially allows the business to function, optimizing for a long duration. LED lights are used extensively in the aviation, healthcare, and manufacturing industries because of low maintenance and high return on investment.

Easy No-Fail Switch

It is already established that LED lights work for a longer duration without needing to be switched off from time to time. But even if the switch were turned on and off for many continuous cycles, it would cause no damage to the light. LED lights do not lose their life when constantly switched on at industrial facilities. Even if there is energy fluctuation, it will not impact the performance and efficiency of LED lights.

Applications Of LED Industrial Lights

LED industrial lights have great applications across different sectors. LED industrial lights can be used as complete fixtures and also as retrofits. LED industrial lights are used in factories and chemical plants without becoming hazardous to health. Here are some specific applications for LED industrial lights.

LED Warehouse Lighting

When we talk about a warehouse, only LEDs can work well and be the most efficient. One reason commercial LED warehouse lighting should be used for an aware house is because it reduces the warm-up time before the daily operations begin. Many other lighting options take some time before reaching their full brightness, which wastes a lot of energy and leads to higher electricity bills. It becomes very inconvenient for factory workers who will have to come early to switch on the lights before they can begin their daily work.

The second advantage of LED lights in warehouses is that the dimming can be adjusted as per requirements. The intelligent lighting feature improves adaptability depending on the functionality and daily operations. Industrial applications are various, and one may need to switch the lights on and off depending on the application. Many lights usually fuse or malfunction with constant switching on and off. LED lights hold valence in situations and help create a bright environment for manufacturing.

LED Industrial Workshop Lighting

Industrial workshops operate on specific principles and require good lighting for everything to go smoothly. The best lighting for industrial workshops is LED lamps and fixtures that provide adequate brightness at a reduced cost. LED lights are very bright and last more than 50000 hours. They are more energy-efficient than fluorescent lamps and make for an economical choice because of less energy consumption.

LED Industrial Parking Lot Lights

For any industrial parking lot, one requires the right lighting solutions for the best results. Suppose any kind of repair and replacement needs to be made to the older model of lights. In that case, industrial parking lot lights should always be replaced because of more brightness and higher energy efficiency.

For any industrial parking lot, LED pole lights are used extensively. Flood lights are the second option used for industrial parking lots with a wide beam angle so that a large area can be covered with fewer installations. LED lights should also follow the industrial requirement of lighting level in a parking lot.

LED Industrial Explosion-Proof Lighting

Explosion-proof lighting is any bulb that will not explode when exposed to specific environmental conditions. It is especially important in industrial areas with a lot of exposure to different chemicals and high temperature and pressure conditions. Many LED lighting options are explosion-proof, even in chemical plants.

LED Industrial Office Lighting

LED lights work well for an industrial office and give a more professional appearance. Since LED lights avoid a range of color temperatures, they are very good for different office applications. Typically, any office will benefit from cooler temperatures like blue and white so that concentration and focus can remain during working hours. Industrial office lighting is excellent for open spaces of an industrial office and will light up the interior quickly.

Types Of LED Lights Used In Industrial Areas

There is no shortage of LED lights, making them very versatile to use in industrial areas. The industrial applications depend on their type and the context in which they can be used. Industrial series, outdoor settings like parking lots, industrial offices, and workshops. Here are some major types of LED lights used across different industrial areas.

Industrial LED High Bay Lights

LED lighting is used in different industries to save costs and make it more efficient in the long round. One can make significant savings and utility bills after the upfront investment of initial installation. LED high bay lights do not emit heat of any kind, so overheating and possible explosion are out of the question.

Additionally, they also last about 10 times as long as any fluorescent option and give better brightness than any other alternative. Industrial LED high bay lights do not show any kind of flickering or intensity variations if there is any change in the energy supply to the industrial area. They are also very durable and require little to no maintenance during their entire lifespan.

Low Bay Industrial LED Lighting

Low bay industrial LED lighting is installed at a height different from high bay industrial lighting. It is a great energy-efficient solution for different industrial applications depending on the feeling height and factory processes. They will help save costs and give the workers an excellent area to operate heavy equipment and machinery. They will not lose their intensity even if the switch is flicked on and off constantly. Any reliable manufacturer will provide food quality and low-bay industrial lights for better illumination across the floor.

Industrial LED Flood Lights

The primary purpose of industrial LED flood lights is to light up the outdoor area of any factory or industry. It is instrumental in parking lots and houses where a large number of things need to be observed at once. Flood lighting is usually done to alert security about any possible intrusions into the facility.

It can also alert us about changes in the environment, like hazardous explosions in chemical plants. The best part about flood lights is that they give a very high-intensity light so that everything in the vicinity is lit up without being left out. These types of industrial lighting are eco-friendly and give a better incentive for businesses to save on costs without compromising functionality.

Industrial LED Panel Lights

Panel lights have multiple applications and also offer significant benefits in the industrial setting. Panels in LED lighting come in different shapes and sizes depending on their installation place. Panel lights are usually installed in the ceiling and can come in different shapes and depths. They are also calLED recessed lighting and can be used for different types of LED bulbs depending on the light intensity. Industrial LED panel lights will be bigger than residential or commercial ones.

The panels have to cover a large manufacturing area so that everything can be seen clearly. Along with LED bulbs and tube lights for larger panels in an industrial setting. The most common shapes for smaller panels include circular, square, rectangular, and oval. Bigger industrial panel lights will cover a larger part of the ceiling and provide higher-intensity lights.

Industrial LED Spot Lights

LED spotlights are used to focus on one specific point and give it an intense brightness to enhance visibility from a distance. In an industrial setting, spotlights can be used in multiple ways in both indoor and outdoor settings. Spotlights are used when targeting a specific area so that multiple installations may be required for different locations.

They are very energy efficient, even with high intensity lighting. Different industries benefit from LED spot lighting as it gives them better security measures and prevents toxic hazards.

Industrial LED Outdoor Lights

Outdoor lights in an industrial setting are great for better illumination during the evening and night. Outdoor industrial lighting is usually used on construction sites to prevent safety hazards for anyone venturing at night. Industrial LED outdoor lights are also installed at a height so that a larger area is covered. In parking lots and open-air chemical treatment facilities, outdoor lighting is angled to see the ground through a broad-angle lamp.

LED Industrial Lighting Design Basics

Since we are talking about the industrial requirements, we also have to mention that LED lighting will have different designs based on its applications. Industrial lighting design needs to be perfected so that the daily operations are more efficient for businesses across different industries. Here are some essential design features manufacturers take care of while producing quality LED lights.

LED Industrial Lighting Lumens and Illuminance

The lumen or luminary flux is the total light emitted from any lighting fixture. There should be a set limit for the light emitted by an LED light source in an industrial workspace. The Illuminating Engineering Society of North America (IESNA) has recommended a list of specific thresholds for LED lighting in different industrial workspaces. Following them for optimal efficiency and promoting better production rates is better. Human recommendations in the manufacturing industry depend on the type of mass-produced product.

Any jewelry products or luxury watches will require a lumen recommendation of about 2000 to 3000 lux. On the other hand, electrical equipment only requires about 500 to 750 lux. Across different manufacturing facilities, the finishing and inspection process has a greater lumen recommendation than traditional manufacturing. A business needs to consider these low-bay industrial LED lighting recommendations for optimal production and better-quality products.

LED Industrial Lighting Photometry

In an industrial setting, the LED lights will also be tested for photometry to see if the lighting is efficient and good enough for the production process. Photometry is a scientific process that considers the intensity of light. Measuring the amount of light produced is essential for seeing if it is adequate for specific room sizes. The equipment and machinery should be well-illuminated, and the environment should be comfortable for the workers. One way to go about photometry is through the lumen calculations, which are done in case of inspections.

LED Industrial Lighting Color Temperature and CRI

Industrial setting LED lights should always go towards and lower color temperature to increase the brightness. Cooler color temperatures include blue and white light, which is excellent for manufacturing and other inspections. The color temperature of an LED light is measured in Kelvin.

On the other hand, the CRI is mentioned in numbers, and the value of 80 is said to be great for any industrial space. The higher the CRI number, the better the color rendition of light. Any value above 90 is considered excellent. The CRI and the range of color temperatures can be checked by the business to find which suits the industrial applications better.

Budget

The budget should be considered before purchasing LED industrial lighting. If an industry needs to switch to LED lighting, the initial cost may be high because all fixtures will need to be installed with LED lights. Industrialists aim to reduce costs in the long run to get better results and a good return on investment. The industrial LED spot lights give a great result and help maintain the finances of the business better. They will be using less energy, saving up on the overall utility bills in any industrial facility.

LED Industrial Lighting Quality and Maintenance

LED industrial lighting has a big benefit of offering little to no maintenance to its users. Different industries will be saving on maintenance costs after switching to LED lighting. The quality of LED lights is incompatible and offers great intensity depending on the application. It is more reliable and durable than any other type of industrial lighting and has a longer lifespan of more than 50000 hours.

Shining a Light on Sustainability: LED’s Eco-Friendly Journey

Green from the Start

The journey of LED lights towards sustainability begins in their manufacturing. The industry is leaning into eco-friendly practices, using recyclable materials and slashing hazardous substances, all while keeping energy use low.

Built to Last

LEDs are champions of longevity, significantly reducing the cycle of waste. Their durability means fewer replacements, less manufacturing demand, and, importantly, less waste ending up in landfills.

End of the Road, Not the Responsibility

When LEDs do reach their end, recycling is key. Though they’re more complex to recycle than traditional bulbs, efforts are increasing to ensure LEDs don’t just end up as e-waste but are instead broken down responsibly, reclaiming valuable materials.

Tackling the E-Waste Challenge

The push against electronic waste is gaining momentum. With regulations tightening and recycling programs expanding, the disposal of LEDs is becoming more environmentally conscious, ensuring these bulbs brighten our future in more ways than one.

Future Bright with Eco-Innovation

Looking ahead, the LED industry is not standing still. Innovations in sustainable materials and recycling technologies promise to further reduce the environmental footprint of these essential lights.

In the grand scheme of things, LED lights are more than just energy savers; they’re a beacon of sustainable practices from production to disposal, illuminating the path to a greener future.

Conclusion

LED industrial lighting is a game-changer for all businesses across different industries. It is a way to get a good return on investment and optimum illumination according to the lumen recommendations. The color temperature and CRI should be looked into to find suitable options for an industrial workspace.

Many manufacturers produce different types of LED lighting to be used in an industrial setting. All of them have different applications and features depending on the installation location. You can ask for a free quote depending on the industry’s needs through a reliable manufacturer if you want to switch to LED.